What Are Chocks On Ships?

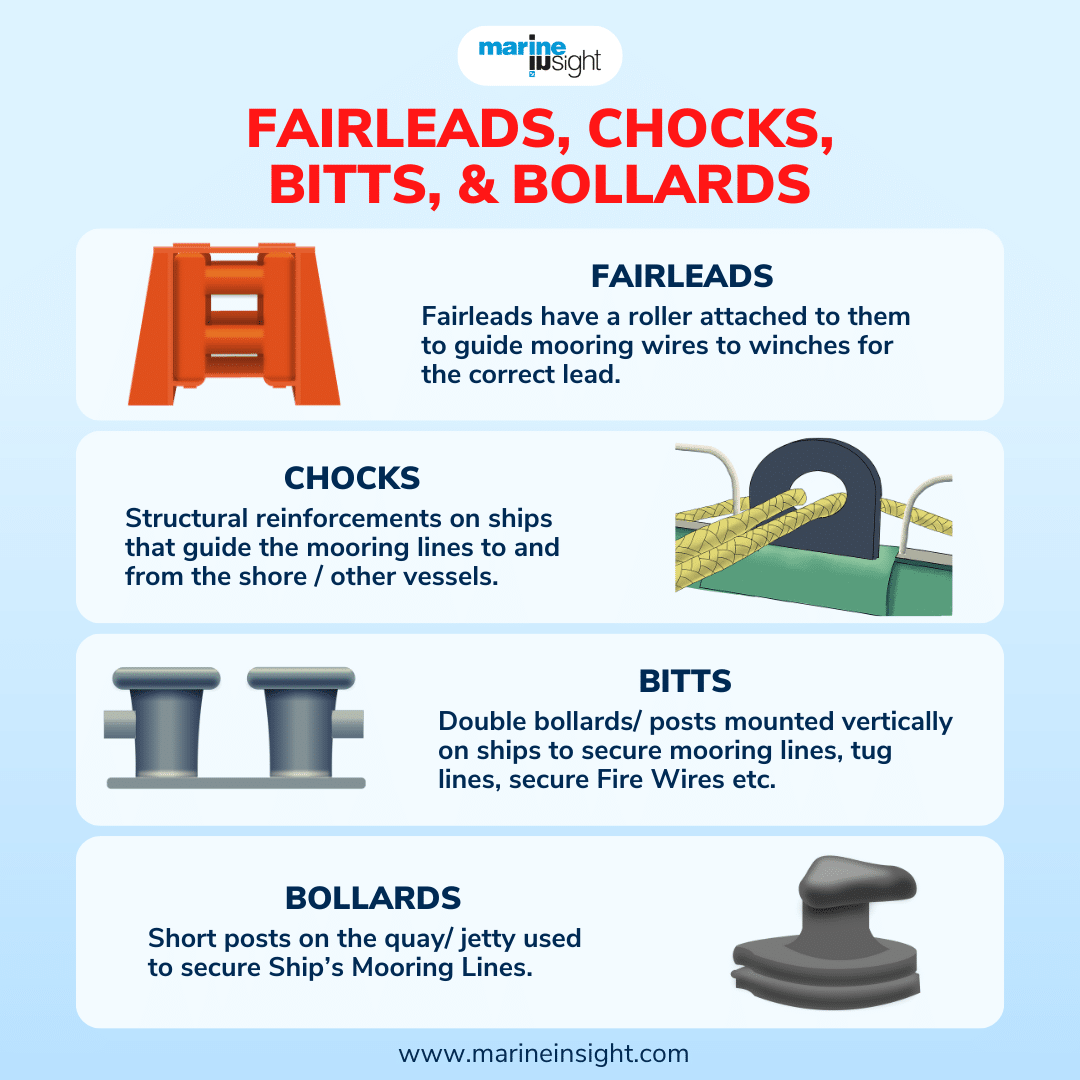

Chocks are intermediate outfitting units that act as guiding and supporting members and through which the ropes are passed while passing from the point of origin (bollard, fairlead, bitt, winch) to the point of fixity (tug, jetty, pier, etc.). Moreover, they also absorb loads from the mooring or towing lines while fastening or securing the vessel.

Mooring and towing operations are indispensable to every vessel. During these operations, various outfitting apparatus are used to secure and fasten the vessel to the quay, jetty, pier, etc. (for mooring) and another ship like a tug (for towing).

The towing or mooring lines (cables, ropes) originate at a deck unit like a bollard, fairlead, bit, or winch and are fastened to the jetty (for mooring) or vessel (for towing).

Design, construction, and types

Chocks are primarily simple in construction, resembling a sizeable hook-like appearance with an opening or slot through which the towing or mooring lines pass. They are mainly composed of cast steel or other breeds of high-strength steel and are robustly built.

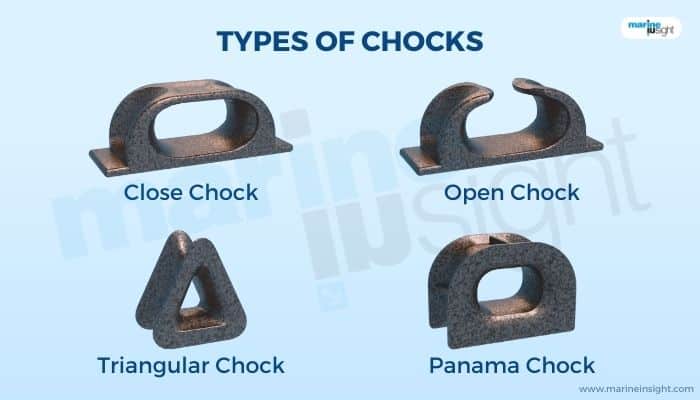

Based on their design and construction, some of the types are:

- Closed Chocks

- Open Chocks

- Panama Chocks

- Mooring pipes

- Triangular chocks

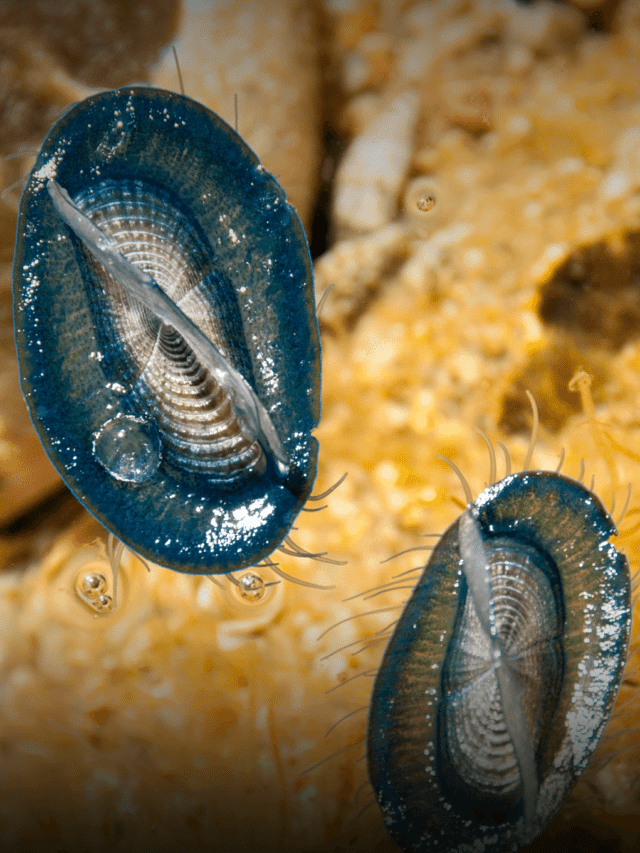

Closed chocks are the most common types and resemble a closed hoop or ring through which the lines can pass. Panama chocks are special closed chocks typical to vessels passing through the Panama Canal, hence the name. These common chocks resemble a perfect elliptical or filleted rectangular ring. Open chocks are characteristic of slots instead of closed rings. Triangular ones are similar to closed chocks but resemble triangular rings rather.

Based on their disposition, chocks are again mainly of two broad types:

- Deck mounted

- Bulwark type

Deck-mounted ones are directly welded to a ship’s main or strength deck through a lower foundation or seat. They are oriented vertically. Bulwark types are simply fitted into the bulwarks atop the side shell at deck edge level.

They are more like holes or rings with side reinforcement directly connected to the bulwark, through which the lines passing get intermediate support and are guided to the external point of attachment.

Depending on the requirement, either of the types is used or a combination of both. Closed chocks, Panama chocks, and triangular chocks can be both decks mounted or bulwark type. Open chocks directly welded to the deck are deck-mounted, while simpler configurations like mooring pipes are bulwark or side-shell mounted.

The size of the chocks is based on the ship type and size, the proportional size of the lines, and the overall mooring and towing arrangement. Multiple towing or mooring lines can pass through a single chock if required. These large chocks, also known as double chocks, have a diameter of 0.1 square metres. They also have higher load-bearing capacity than ordinary chocks through which a single line can be passed.

The safety of the chocks is ascertained only after specific tests for reliability. The chock arrangement and the chocks’ quality must conform to IACS requirements and classification guidelines. Moreover, they also have to meet the material and construction standards per certification authority regulatory guidelines like that of ISO, JIS, DIN, etc.

Some of the essential design factors taken into consideration while choosing chocks for a particular towing or mooring arrangement are:

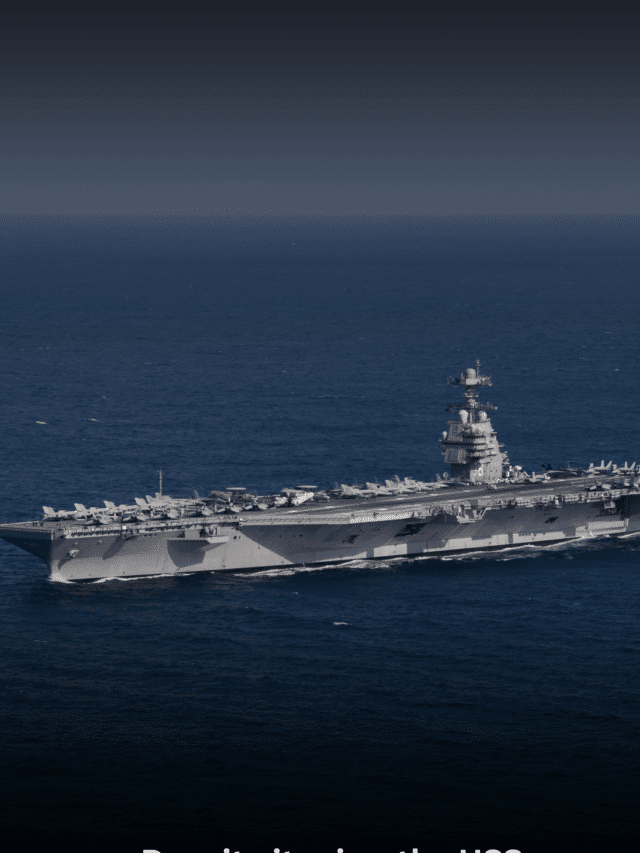

Size and type: These are per the arrangement requirements and the vessel. Larger vessels that require large mooring and/or towing lines and an extensive system of such an arrangement presuppose larger-sized chock units and the proper type of them in adequate numbers.

Disposition: This is related to the above point. Furthermore, the disposition also depends on the number of chocks and the arrangement of other items on the deck.

Strength and Construction: The main determinants are the induced forces or loads, the resultant type of mooring or towing, and the type of lines used.

However, the strength requirements of the vessel itself are also crucial as well. The disposition of chocks is done so as they are placed on the areas on the deck that are strengthened, in the way of stiffeners or deep members, to prevent localised high stresses on the deck.

We shall discuss the loading aspects of chocks in the next part.

Forces and Design loads

The most crucial factor for choosing a chock as a part of the towing or mooring arrangement is the loads acting on the lines translated from vessel action. The chocks are designed considering the maximum extent of loads expected to act on it from the towing or mooring lines and hence are also quality tested accordingly. This maximum extent of loading is different for towing and mooring.

For towing, where for all practical purposes, the vessel should be pulled by a tug, the highest amount of feasible load that should act on the chock is taken as the maximum bollard pull of the tug on the vessel induced on the lines. Similarly, the maximum expected force on the mooring lines (and transferred to the chock) during mooring operations is taken as the Ship Design Minimum Breaking load (MBLSD).

This is the minimum force capable of breaking away a dry, new, and taut rope under the influence of vessel action during mooring procedures. The MBLSD, in turn, depends on the design limits of the vessel, the type of mooring procedure, and external factors of the sea as per guidelines.

However, like all other design considerations, the working or allowable stress on the chock is kept less than the ultimate design value of stress beyond which it failed. Though highly variable, the working limit for this stress is taken as 85% of the breaking limit for all practical purposes.

How do the forces act on the chock?

During operation, the forces arising from vessel action onto the towing or mooring lines get transferred onto the chocks that act as guides and supports. The forces act in two ways:

Horizontal: The loads acting on the chock arise as tensile components of the rope or line acting at a definite orientation per the arrangement. The disposition of the towing and mooring arrangement decides the loads acting on the chock.

Vertical: Similarly, the loads act in a vertical sense as well as shown. This action is similar to a mechanical pulley.

You might also like to read-

- What is Mooring of Ships?

- What Are Liftgate Services?

- 5 Stages Of Marine Machinery Installation On Ships

- 10 Important Points to Remember During Mooring Operation On Ships

- Important Points For Carrying Out Maintenance of Mooring Ropes and Wires On Ships

- 10 Important Points For Ship’s Mooring Equipment Maintenance

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used in the article, have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

Subhodeep is a Naval Architecture and Ocean Engineering graduate. Interested in the intricacies of marine structures and goal-based design aspects, he is dedicated to sharing and propagation of common technical knowledge within this sector, which, at this very moment, requires a turnabout to flourish back to its old glory.